It factors in direct materials, direct labor, and overhead costs by analyzing departmental expenses rather than tracking costs per individual unit, which facilitates an average production cost calculation. Why have three different cost calculation methods for process costing, and why use one version instead of another? The different calculations are required for different cost accounting needs.

Calculate the equivalent units to account for the number of unfinished items at the end of the period

Process costing has the process of being easier to use than other costing methods, and it can assist businesses in costing areas for possible cost savings. Process costing is used for products produced in large quantities that are identical, such as bricks or soda cans. On the other hand, job costing is used for unique or custom-made products, such as custom-designed wedding dresses. Once a cost per unit has been determined, it must be split between finished goods ready to be sold or shipped and unfinished products still in progress on the assembly line. Process costing helps in performance evaluation by providing information on the costs incurred in each stage of the production process, which allows for measuring the efficiency and effectiveness of the production process. This article will explore the definition and types of process costing, its importance in manufacturing, and its advantages and disadvantages.

A Guide to Effective Inventory Management

The choice of method depends on how a business tracks inventory and expenses over time. Industries that rely on process costing include manufacturing, retail, food production, pharmaceuticals, and chemical processing. Businesses in these sectors operate with standardized production processes, making process costing an essential tool for accurate cost retained earnings tracking and financial planning. Process costing is a method used to track production costs in industries that manufacture large volumes of identical products. It ensures accurate cost allocation, helping businesses improve pricing, efficiency, and profitability.

Processing Expenses with the Process Cost System

Raw ingredients flow continuously through the production cycle, culminating in the production of identical paper packets. Conversion costs $100,000, or $.67 per package, including $70,000 in direct work and $30,000 in overhead, which includes maintenance, insurance, and power. The overall cost is $150,000, with 150,000 units produced at a cost of $1 each unit. By integrating process costing with financial reporting, BrightPearl provides better visibility into production costs, helping businesses track expenses, reduce errors, and improve efficiency. Whether managing a small operation or scaling production, BrightPearl makes cost management easier and more reliable. FIFO is beneficial in industries where material prices fluctuate significantly, such as pharmaceuticals, electronics, and oil refining, as it ensures that the most up-to-date material costs remain in inventory.

- Process costing is a method in cost accounting for compiling manufacturing costs and assigning them to the units produced.

- Look at the expense categories and note each overhead cost and the amount spent before.

- Various accounting software providers offer process-costing tools to help you organize this process.

- The first step is to assess the flow of inventory during the accounting period.

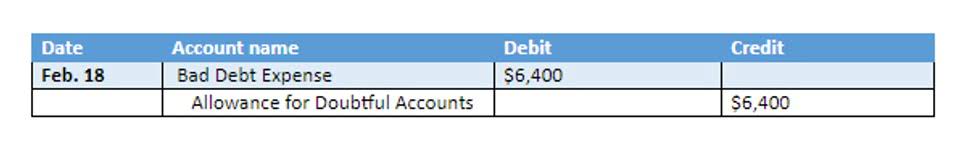

- This follows the expense recognition principle because the cost of the product is expensed when revenue from the sale is recognized.

- Process costing splits expenses like energy, labor, and direct materials into manageable costs per ton, allowing for transparency in pricing and profitability assessment.

Material Resource Planning (MRP)

Each job is different, depending on the size of the home, whether or not the items are packed ahead of time or process cost system to be packed in advance of the move, and the distance between homes. Dedicated to keeping your business finances operating smoothly so you can focus on your business. An experienced accountant not only ensures compliance with tax laws but also provides strategic financial advice that can drive business growth…. A grocery store’s analysis of a recent customer survey finds an increasing number of customers interested in being able to custom-order meals to go. Maria sees this as an opportunity to enter a niche market for busy families or individuals who want home-cooked meals with a variety of options and combinations, but who have little time.

This follows the expense recognition principle because the cost of the product is expensed when revenue from the sale is recognized. If the equivalent of 100,000 units were processed in June, the per unit costs will be $1.50 for direct materials and $2.25 for conversion costs. These costs will then be transferred to second department where its processing costs will be added. The textile industry uses process costing to calculate the cost of producing fabrics. This industry produces fabrics in large quantities with a consistent manufacturing process, making process costing an appropriate technique.

- Instead of tracking costs per unit, as in job costing, process costing averages the costs up and down the manufacturing process.

- Process costing is appropriate for companies that produce a continuous mass of like units through series of operations or process.

- The standard cost method assigns predetermined costs to the different stages of production based on estimates of the cost of producing one output unit.

- Moreover, raw material needs to pass through multiple stages of production before turning into finished goods.

- This costing system is used when the costs of producing each individual unit are very similar, and it is difficult to track the costs for each individual unit throughout the production process.

Instead, the company accumulates costs—such as raw materials, labor, and overhead—by department over a period, like a month, and then divides the total cost by the number of gallons produced to determine the cost per unit. This method ensures consistent cost assignment across all units in a highly uniform production environment. A process costing system is used to allocate costs in industries where production is continuous and units are indistinguishable from one another, such as in manufacturing chemicals, food, or textiles. In this system, costs are accumulated by department or production process over a specific period and then averaged over all units produced during that time. This approach simplifies cost tracking by treating all units as identical, allowing businesses to determine the cost per unit by dividing total process costs by the number of units completed. It is especially effective for mass production environments with consistent, standardized outputs.

Process costing is a method wherein the products go through two or more processes. The costs are assigned/charged to individual processes or operations, averaged over the number of units produced during the said period. It is used commonly in manufacturing units like paper, steel, soaps, medicines, vegetable oils, paints, rubber, chemical, etc. https://cassianconsulting.com/en/manufacturing-and-non-manufacturing-costs-online/ use this method widely. Let’s assume, a manufacturing business completed 4,000 products and has another 1,000 units halfway through production, the total costs would be divided by 4,500 units